Reduction of Microbial Contamination in Kaolin from Belitung Island, Indonesia http://www.doi.org/10.26538/tjnpr/v7i1.3

Main Article Content

Abstract

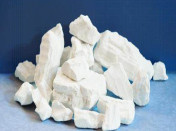

Kaolin is often used as an excipient in pharmaceutical and cosmetic industries as well as an anticaking, bulking, absorbent, and opacifying agent. It is also required in some cosmetic industries with a limited number of microbial contaminations, but no study has explored the reduction of these contaminant microbes based on the requirements. Therefore, this study aims to produce kaolin that complies with the microbial contamination specifications. Several methods were used in this study to reduce the microbial content, including heating, sterilization using an

autoclave, as well as soaking with ethanol, methanol, and chloroform. The number of microbial contaminations was then measured using the Petri dish method. The result showed that the 2 h heating treatment was not sufficient to eliminate microbial contamination even at a temperature of 250°C, hence, it was combined with the addition of sodium hypochlorite to obtain a better outcome. Furthermore, autoclave treatment at 121°C for 20 min with or without pre-treatment successfully reduced the population of microbes to <102 per gram and this met the standard

requirement for cosmetic industries.

Downloads

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Murray HH. Traditional and new applications for kaolin,smectite, and palygorskite: A general overview. Appl Clay Sci. 2000; 17(5-6):207-221.

Iannicelli J. High extraction magnetic filtration of kaolin clay. Clays Clay Miner. 1976;24(2):64-68

Chun YK. Removal of iron from hard pulverised kaolin by dry high-gradient magnetic separation. Magn Electr Sep. 1995; 6(3):171-177

Mesquita LMS De, Rodrigues T, Gomes SS. Bleaching of Brazilian Kaolins using Organic Acids and Fermented Medium. Biotechnology. 1996;9(9):965-971.

Musiał I, Cibis E, Rymowicz W. Designing a process of kaolin bleaching in an oxalic acid enriched medium by Aspergillus niger cultivated on biodiesel-derived waste composed of glycerol and fatty acids. Appl Clay Sci. 2011; 52(3):277-284

Hosseini MR, Pazouki M, Ranjbar M, Habibian M. Bioleaching of iron from highly contaminated Kaolin clay by Aspergillus niger. Appl Clay Sci. 2007; 37(3-4):251-257

Holešová S, Hundáková M, Pazdziora E. Antibacterial Kaolinite Based Nanocomposites. Procedia Mater Sci. 2016;12:124-129

Belver C, Bañares Muñoz MA, Vicente MA. Chemical activation of a kaolinite under acid and alkaline conditions. Chem Mater.

Kogel JE. Mining and processing kaolin. Elements. 2014;10(3): 189-193

Wardhana YW, Hasanah AN, Primandini P. Deformation and adsorption capacity of kaolin that is influenced by temperature variation on calcination. Int J Pharm Pharm Sci. 2014;6(SUPPL. 3):1-2.

Ryu HW, Cho KS, Chang YK, Kim SD, Mori T. Refinement of low-grade clay by microbial removal of sulfur and iron compounds using Thiobacillus ferrooxidans. J Ferment Bioeng. 1995; 80(1):46-52

Lee EY, Cho KS, Wook Ryu H. Microbial refinement of kaolin by iron-reducing bacteria. Appl Clay Sci. 2002; 22(1- 2):47-53

Guo MR, He QX, Li YM, Lu XQ, Chen ZL. Removal of Fe from kaolin using dissimilatory Fe(III)-reducing bacteria. Clays Clay Miner. 2010;58(4):515-521

Guo MR, Lin YM, Xu XP, Chen ZL. Bioleaching of iron from kaolin using Fe(III)-reducing bacteria with various carbon nitrogen sources. Appl Clay Sci. 2010; 48(3):379-383

Drew SM, Bruns JC, Kogel JE. United States Patent ( 19 ) 11 Patent Number : BATTERY-49. United States Pat. Published online 1997:1-7

Donlan RM, Elliot DL, Kapp NJ, Wiatr CL, Rey PA. United States Patent ( 19 ). Published online 2000:1-16.

Sinegani AAS, Hosseinpur A. Evaluation of effect of different sterilization methods on soil biomass phosphorus extracted with NaHCO3. Plant, Soil Environ. 2010; 56(4):156-162

Berns AE, Philipp H, Narres HD, Burauel P, Vereecken H, Tappe W. Effect of gamma-sterilization and autoclaving on soil organic matter structure as studied by solid state NMR, UV and fluorescence spectroscopy. Eur J Soil Sci. 2008; 59(3):540-550