Effects of Three Modified Starches on The Physicochemical Properties of Chitosan-Based Packaging Film

Main Article Content

Abstract

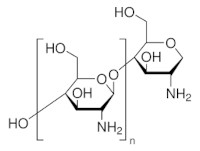

Starch, as a biopolymer, due to its availability and low cost, could be a promising new packaging solution for biodegradable packaging. However, its weak functional properties require measures such as limiting interactions with certain hydroxyl groups and exploring mixtures with other polymers to enhance its effectiveness. In this study, films were prepared from various modified starches (E1412, E1414, and E1420) at different concentrations (2%, 4%, 6%, and 8% w/v), with a combination of 2% chitosan (CH) at different ratios (2:8, 3:7, 4:6, and 5:5 v/v). The impact of these chitosan ratios on important parameters, including water vapor transmission rate, tensile strength (TS), percentage elongation at break (EAB), elastic modulus (EM), and stiffness The transparency of the membrane has been thoroughly inspected. Through protonation, the amino groups of chitosan catalyze the formation of intermolecular bonds, thereby enhancing the tensile strength and water-repellent properties of the starch film. Notably, experimental findings highlighted that the coating containing 4% E1412-chitosan at a ratio of 5:5 (v/v) exhibited the strongest water vapor barrier. Therefore, these composite films have emerged as a promising avenue for developing environmentally friendly packaging solutions in the food industry.

Downloads

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

1. Grigoriadi, K., Barkoula, N. M., and Ladavos, A. Preparation and characterization of acetylated corn starch-(PVOH)/clay nanocomposite films. Carbohydr Polym. 2014;102(1):216-222. doi:10.1016/j.carbpol.2013.11.030

2. Colussi, R., Pinto, V. Z., El Halal, S. L. M., Biduski, B., Prietto, L., Castilhos, D. D., ... and Dias, A. R. G. Acetylated rice starches films with different levels of amylose: Mechanical, water vapor barrier, thermal, and biodegradability properties. Food Chem. 2017;221:1614-1620. doi:10.1016/j.foodchem.2016.10.129

3. Combrzyński, M., Oniszczuk, T., Kupryaniuk, K., Wójtowicz, A., Mitrus, M., Milanowski, M., and Matwijczuk, A. Physical properties, spectroscopic, microscopic, x-ray, and chemometric analysis of starch films enriched with selected functional additives. Materials. 2021;14(10). doi:10.3390/ma14102673

4. Calambas HL, Fonseca A, Adames D, Aguirre-Loredo Y, Caicedo C. Physical-mechanical behavior and water-barrier properties of biopolymers-clay nanocomposites. Molecules. 2021;26(21). doi:10.3390/molecules26216734

5. Aranaz, I., Alcántara, A. R., Civera, M. C., Arias, C., Elorza, B., Heras Caballero, A., and Acosta, N. Chitosan: An overview of its properties and applications. Polymers (Basel). 2021;13(19). doi:10.3390/polym13193256

6. Lipatova IM, Losev N V., Makarova LI, Rodicheva JA, Burmistrov VA. Effect of composition and mechanoactivation on the properties of films based on starch and chitosans with high and low deacetylation. Carbohydr Polym. 2020;239. doi:10.1016/j.carbpol.2020.116245

7. Zheng, K., Xiao, S., Li, W., Wang, W., Chen, H., Yang, F., and Qin, C. Chitosan-acorn starch-eugenol edible film: Physico-chemical, barrier, antimicrobial, antioxidant and structural properties. Int J Biol Macromol. 2019;135:344-352. doi:10.1016/j.ijbiomac.2019.05.151

8. Tsai MJ, Weng YM. Novel edible composite films fabricated with whey protein isolate and zein: Preparation and physicochemical property evaluation. LWT-Food Science and Technology. 2019;101:567-574. doi:10.1016/j.lwt.2018.11.068

9. K. SS, Indumathi MP, Rajarajeswari GR. Mahua oil-based polyurethane/chitosan/nano ZnO composite films for biodegradable food packaging applications. Int J Biol Macromol. 2019;124:163-174. doi:10.1016/j.ijbiomac.2018.11.195

10. Colivet J, Carvalho RA. Hydrophilicity and physicochemical properties of chemically modified cassava starch films. Ind Crops Prod. 2017;95:599-607. doi:10.1016/j.indcrop.2016.11.01

11. Bangyekan C, Aht-Ong D, Srikulkit K. Preparation and properties evaluation of chitosan-coated cassava starch films. Carbohydr Polym. 2006;63(1):61-71. doi:10.1016/j.carbpol.2005.07.032

12. Xu YX, Kim KM, Hanna MA, Nag D. Chitosan-starch composite film: Preparation and characterization. Ind Crops Prod. 2005;21(2):185-192. doi:10.1016/j.indcrop.2004.03.002

13. Zamudio-Flores PB, Bautista-Baños S, Salgado-Delgado R, Bello-Pérez LA. Effect of oxidation level on the dual modification of banana starch: The mechanical and barrier properties of its films. J Appl Polym Sci. 2009;112(2):822-829. doi:10.1002/app.29433

14. Wong DWS, Gastineau FA, Gregorski KS, Tillin SJ, Pavlath AE. Chitosan-Lipid Films: Microstructure and Surface Energy. J Agric Food Chem. 1992; 40:540-544.