Pectin-Starch Biocomposite Reinforced with Rattan-Derived Cellulose Nanocrystals: A Study of Mechanical and Water Absorption Properties

Main Article Content

Abstract

Downloads

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Jantrawut P, Chaiwarit T, Jantanasakulwong K, Brachais CH, Chambin O. Effect of plasticizer type on tensile property and in vitro indomethacin release of thin films based on low-methoxyl pectin. Polymers. 2017;9(289):1-14. Doi: 10.3390/polym9070289

Mada T, Duraisamy R, Guesh F. Optimization and characterization of pectin extracted from banana and papaya mixed peels using response surface methodology. Food Sci Nutr. 2022;10(4):1222–1238. Doi: 10.1002/fsn3.2754

Swamy GJ, Muthukumarappan K. Optimization of continuous and intermittent microwave extraction of pectin from banana peels. Food Chem. 2017;220:108–114. Doi: 10.1016/j.foodchem.2016.09.197

Bátori V, Jabbari M, Åkesson D, Lennartsson PR, Taherzadeh MJ, Zamani A. Production of Pectin-Cellulose Biofilms: A New Approach for Citrus Waste Recycling. Int J Polym Sci. 2017;9732329:1-9. Doi: 10.1155/2017/9732329

Fath MT Al, Nasution H, Harahap H, Ayu GE. Biocomposite of pectin and starch-filled with nanocrystalline cellulose (NCC): The effect of filler loading and glycerol addition. AIP Conf Proc. 2019;2175(020012):1-7. Doi: 10.1063/1.5134576

Mellinas C, Ramos M, Jiménez A, Garrigós MC. Recent trends in the use of pectin from agro-waste residues as a natural-based biopolymer for food packaging applications. Materials (Basel). 2020;13(3):1-17. Doi: 10.3390/ma13030673

Chaichi M, Hashemi M, Badii F, Mohammadi A. Preparation and characterization of a novel bionanocomposite edible film based on pectin and crystalline nanocellulose. Carbohydr Polym. 2017;157:167–175. Doi: 10.1016/j.carbpol.2016.09.062

Arooj A, Khan M, Munawar KS. Preparation and physicochemical characterization of starch/pectin and chitosan blend bioplastic films as future food packaging materials. J Environ Chem Eng. 2024;12(111825):1-8. Doi: 10.1016/j.jece.2023.111825

Al Fath MT, Ayu GE, Hasibuan GCR, Dalimunthe NF, Alexander V. The Effect of Glycerol and Sago Starch Addition on the Characteristics of Bioplastics Based on Orange Peel Pectin. Chem Ind Chem Eng Q. 2024;30(4):359–365. Doi: 10.2298/CICEQ231214007A

Dompo SI, Tanor MN, Rahardiyan D, Gedoan SP, Moko EM. Effect of Acid Modification on the Physico-Chemical Properties of North Sulawesi’s Giant Swamp Taro (GST) Starch (Cyrtosperma merkusii). Trop J Nat Prod Res. 2024;8(1):5869–5874. Doi: 10.26538/tjnpr/v8i1.23

Fath MTA, Ayu GE, Lubis M, Hasibuan GCR, Dalimunthe NF. Mechanical And Thermal Properties Of Starch Avocado Seed Bioplastic Filled With Cellulose Nanocrystal (CNC) As Filler And Potassium Chloride (KCl) As Dispersion Agent. Rasayan J Chem. 2023;16(3):1630–1636. Doi: 10.31788/RJC.2023.1638464

Nasution H, Harahap H, Al Fath MT, Afandy Y. Physical properties of sago starch biocomposite filled with Nanocrystalline Cellulose (NCC) from rattan biomass: The effect of filler loading and co-plasticizer addition. IOP Conf Ser Mater Sci Eng. 2018;309(1):1–6. Doi: 10.1088/1757-899X/309/1/012033

Farahnaky A, Saberi B, Majzoobi M. Effect of glycerol on physical and mechanical properties of wheat starch edible films. J Texture Stud. 2013;44(3):176–186. Doi: 10.1111/jtxs.12007

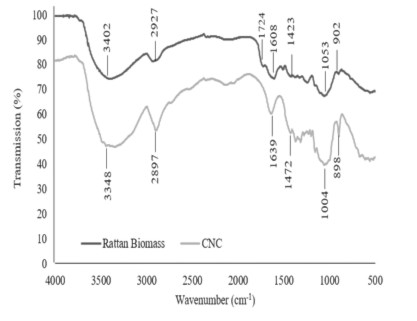

Fath M, Nasution H. Process optimization of manufacturing nanocrystalline cellulose from rattan biomass using sulfuric acid. AIP Conf. Proc. 2018;020020:1-6. Doi: 10.1063/1.5064306

Harahap H, Hayat N, Lubis M. Preparation and application of nanocrystalline cellulose derived from sugarcane waste as filler modified alkanolamide on crosslink of natural rubber latex film. In: AIP Conference Proceedings. AIP Conf. Proc. 2017;(1865)040012:1-6. Doi: 10.1063/1.4993354

Nasution H, Harahap H, Al Fath MT, Afandy Y. Physical properties of sago starch biocomposite filled with Nanocrystalline Cellulose (NCC) from rattan biomass: The effect of filler loading and co-plasticizer addition. IOP Conf. Ser.: Mater. Sci. Eng. 2018;309(01203):1-6. Doi: 10.1088/1757-899X/309/1/012033.

Zainuddin SYZ, Ahmad I, Kargarzadeh H, Abdullah I, Dufresne A. Potential of using multiscale kenaf fibres as reinforcing filler in cassava starch-kenaf biocomposites. Carbohydr Polym. 2013;92(2):2299–2305. Doi: 10.1016/j.carbpol.2012.11.106

Sharma PC, Gupta A, Kaushal P. Optimization of method for extraction of pectin from apple pomace. Indian J Nat Prod Resour (IJNPR)[Formerly Nat Prod Radiance (NPR)]. 2015;5(2):184–189. Doi: 10.56042/ijnpr.v5i2.2182

Perumal AB, Nambiar RB, Sellamuthu PS, Sadiku ER, Li X, He Y. Extraction of cellulose nanocrystals from areca waste and its application in eco-friendly biocomposite film. Chemosphere. 2022;287:1-12. Doi: 10.1016/j.chemosphere.2021.132084

Khan M, Nandkishor. Optimization of Extraction Condition and Characterization of Low Methoxy Pectin From Wild Plum. J Packag Technol Res. 2019;3(3):215–221. Doi: 10.1007/s41783-019-00070-z

Azad AKM. Isolation and Characterization of Pectin Extracted from Lemon Pomace during Ripening. J Food Nutr Sci. 2014;2(2):30-35. Doi: 10.11648/j.jfns.20140202.12

Ismail NSM, Ramli N, Hani NM, Meon Z. Extraction and characterization of pectin from dragon fruit (Hylocereus polyrhizus) using various extraction conditions. Sains Malaysiana. 2012;41(1):41–45.

Mazlita Y, Lee H V, Hamid SBA. Preparation of cellulose nanocrystals bio-polymer from agro-industrial wastes: Separation and characterization. Polym Polym Compos. 2016;24(9):719–728. Doi: 10.1177/09673911160240090

Chu Y, Sun Y, Wu W, Xiao H. Dispersion properties of nanocellulose: a review. Carbohydr Polym. 2020;250(116892):1-17. Doi: 10.1016/j.carbpol.2020.116892

Bilbao-Sainz C, Bras J, Williams T, Sénechal T, Orts W. HPMC reinforced with different cellulose nano-particles. Carbohydr Polym. 2011;86(4):1549–1557. Doi: 10.1016/j.carbpol.2011.06.060

Morán JI, Alvarez VA, Cyras VP, Vázquez A. Extraction of cellulose and preparation of nanocellulose from sisal fibres. Cellulose. 2008;15:149–159. Doi: 10.1007/s10570-007-9145-9

Liew FK, Hamdan S, Rahman MR, Rusop M, Lai JCH, Hossen MF, Rahman MM. Synthesis and characterization of cellulose from green bamboo by chemical treatment with mechanical process. J Chem. 2015;212158:1-7. Doi: 10.1155/2015/212158

Alemdar A, Sain M. Isolation and characterization of nanofibers from agricultural residues–Wheat straw and soy hulls. Bioresour Technol. 2008;99(6):1664–1671. Doi: 10.1016/j.biortech.2007.04.029

Karim MZ, Chowdhury ZZ, Hamid SBA, Ali ME. Statistical optimization for acid hydrolysis of microcrystalline cellulose and its physiochemical characterization by using metal ion catalyst. Materials (Basel). 2014;7(10):6982–6999. Doi: 10.3390/ma7106982

Agustin MB, Ahmmad B, Alonzo SMM, Patriana FM. Bioplastic based on starch and cellulose nanocrystals from rice straw. J Reinf Plast Compos. 2014;33(24):2205–2213. Doi: 10.1177/0731684414558325

Rosa MF, Chiou BS, Medeiros ES, Wood DF, Williams TG, Mattoso LH, Orts WJ, Imam SH. Effect of fibre treatments on tensile and thermal properties of starch/ethylene vinyl alcohol copolymers/coir biocomposites. Bioresour Technol. 2009;100:5196–5202. Doi: 10.1016/j.biortech.2009.03.085

Francucci G, Rodríguez ES, Vázquez A. Study of saturated and unsaturated permeability in natural fibre fabrics. Compos Part A Appl Sci Manuf. 2010;41(1):16–21. Doi: 10.1016/j.compositesa.2009.07.012

Fishman ML, Coffin DR, Unruh JJ, Ly T. Pectin/starch/glycerol films: blends or composites? J Macromol Sci Part A Pure Appl Chem. 1996;33(5):639–654. Doi: 10.1080/10601329608010884

Meneguin AB, Cury BSF, Dos Santos AM, Franco DF, Barud HS, da Silva Filho EC. Resistant starch/pectin free-standing films reinforced with nanocellulose intended for colonic methotrexate release. Carbohydr Polym. 2017;157:1013–1023. Doi: 10.1016/j.carbpol.2016.10.062

Fishman ML, Coffin DR, Onwulata CI, Konstance RP. Extrusion of pectin and glycerol with various combinations of orange albedo and starch. Carbohydr Polym. 2004;57(4):401–413. Doi: 10.1016/j.carbpol.2004.05.014

Miranda CS, Ferreira MS, Magalhães MT, Santos WJ, Oliveira JC, Silva JBA, José NM. Mechanical, Thermal, and Barrier Properties of Starch-based Films Plasticized with Glycerol and Lignin and Reinforced with Cellulose Nanocrystals. Mater Today Proc. 2015;2(1):63–69. Doi: 10.1016/j.matpr.2015.04.009

Liu D, Zhong T, Chang PR, Li K, Wu Q. Starch composites reinforced by bamboo cellulosic crystals. Bioresour Technol. 2010;101(7):2529–2536. Doi: 10.1016/j.biortech.2009.11.058

Lu Y, Weng L, Cao X. Morphological, thermal and mechanical properties of ramie crystallites—reinforced plasticized starch biocomposites. Carbohydr Polym. 2006;63(2):198–204. Doi: 10.1016/j.carbpol.2005.08.027

Vieira SR, da Silva JBA, Druzian JI, de Jesus Assis D, Mussagy CU, Pereira JFB, Santos-Ebinuma VC, Lemos PVF, Correia PR, de Souza Ferreira E, de Souza CO. Cellulose Nanoparticles Prepared by Ionic Liquid-Assisted Method Improve the Properties of Bionanocomposite Films. J Polym Environ. 2022;30(8):3174–3185. Doi: 10.1007/s10924-022-02420-6